PARTS SOURCING

SWT has developed one of the best preventive maintenance programs designed specifically for each machine. We work extensively with CNC Sales & Service for all the electrical components. In addition, our relationship with World Machinery and RAS Machine Tools allows us to source all mechanical CNC parts.

Southwest Technology Inc. is here to help you with all your part ordering needs. With a vast connection of supplier and manufacturers at our disposal, we are sure we can get you up and running in no time.

Please fill out a form below so we can further assist you with all your part sourcing needs.

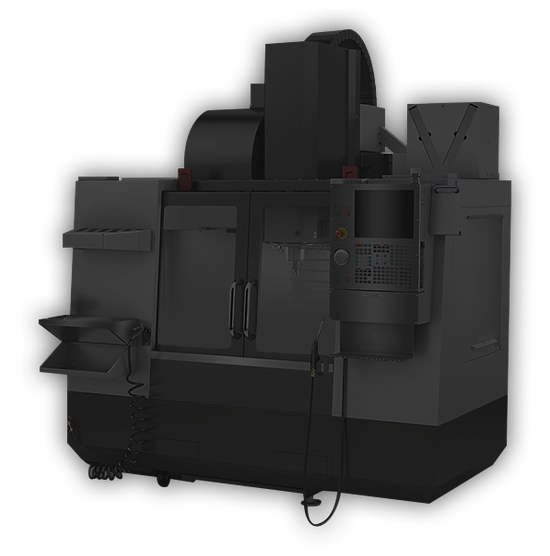

CNC MACHINE SERVICES

When your equipment breaks down, trust our team to efficiently find the right fix. We work diligently to get your heavy machinery running again while ensuring that the problem does not persist. Machine troubleshooting is offered for all facets of your CNC machines. It is our goal to get your machine up and running and ensure that it stays that way. We specialize in Okuma machines and also work on the following: Mori Seiki, Mazak, Wasino, Nomura, Kitamura, Monarch, Hardinge, Bridgeport, Lagun, Hwacheon, Haas, Eurotech and many others. We service Nationwide and Mexico SWT is located in Southern California.

Tool changers often require alignment and repairs for various reasons. Maintaining a well functioning automatic tool changer is key for ensuring your machine is working efficiently.

Southwest Technology can replace, source, or maintain your ball screw/bearings and keep your machine running smoothly

Southwest Technologies Inc. offers maintenance and repairs services for all tailstock manufacturers including the replacement and/or refurbishing of all worn parts.

Southwest Technology Inc. inspects and insure everything is running parallel with the Z-axis as well as cut on center with the part. A properly aligned turret is critical to any machining process.

Southwest Technology Inc. can provide the spindle repair, maintenance and restoration that will ensure that you get the most out of your CNC machine regardless of brand or manufacturing industry.

Southwest Technology Inc. is also experienced in all electronic applications. We can handle replacements, maintenance and or installs for VAC Drives, Axis Drives, CPU's or Power supplies.

We also offer services regarding Hydraulics, Pneumatics and Software related applications.

Southwest can help you keep your machine running true and precise. We offer alignment services to ensure you are cutting as precise and accurate as possible.

SPINDLES

Southwest Technology Inc. can provide the spindle repair, maintenance and restoration that will ensure that you get the most out of your CNC machine regardless of brand or manufacturing industry.

TURRETS

Southwest Technology Inc. inspects and insure everything is running parallel with the Z-axis as well as cut on center with the part. A properly aligned turret is critical to any machining process.

TOOL CHANGER

Tool changers often require alignment and repairs for various reasons. Maintaining a well functioning automatic tool changer is key for insuring your machine is working efficiently.

BALL SCREW / BEARINGS

Southwest Techonology can replace, source, or maitain your ball screw/bearings and keep your machine running smoothly

TAILSTOCKS

Southwest Technology Inc. offers maintenance and repairs services for all tailstock manufacturers including the replacement and/or refurbishing of all worn parts.

MACHINE GEOMETRY

Let us help you keep your machine running true and precise. We offer alignment services to ensure you are cutting as precise and accurate as possible.

ELECTRONICS

Southwest Technology Inc. is also experienced in all electronic applications. We can handle replacements, maintenance and or installs for VAC Drives, Axis Drives, CPU's or Power supplies.

OTHER SERVICES

We also offer services regarding Hydraulics, Pneumatics and Software related applications. Please visit our Contact Us page and request more information.

PREVENTATIVE MAINTENANCE

SOLUTIONS

To assist with your requirements for performance, accuracy, reduced downtime, and machine tool life, our team will customize a preventative maintenance program for your equipment. With this program, we will deliver detailed checklists for each machine in your inventory as well as provide Renishaw Ballbar accuracy testing to meet ISO standards. We will also work with you to schedule machine maintenance at a time that best fits with your business’s needs. Overall with a preventative program, our team will work to find and correct problems before they lead to costly downtime.

WORKHOLDING

We are excited to announce that Southwest Technology Inc. has partnered with Kitagawa Workholding to deliver cutting-edge precision and efficiency in machining solutions. This collaboration brings together Southwest Technology's expertise in maintenance and repair with Kitagawa's industry-leading workholding solutions, ensuring superior performance and reliability for our customers.

Southwest Technology Inc. is proud to be a Certified Rotary Table Rebuilder for Kitagawa Workholding, ensuring top-quality repairs and rebuilds that restore performance to factory standards. This certification guarantees that our team uses genuine parts, expert techniques, and precise calibrations to extend the life of your rotary tables. Customers benefit from improved reliability, enhanced machining accuracy, and cost savings compared to full replacements. Trust Southwest Technology Inc. to keep your Kitagawa rotary tables running at peak efficiency!

WORKHOLDING REPAIR

We can maintain your current workholding or install new parts as needed. Maintenance for workholding includes: